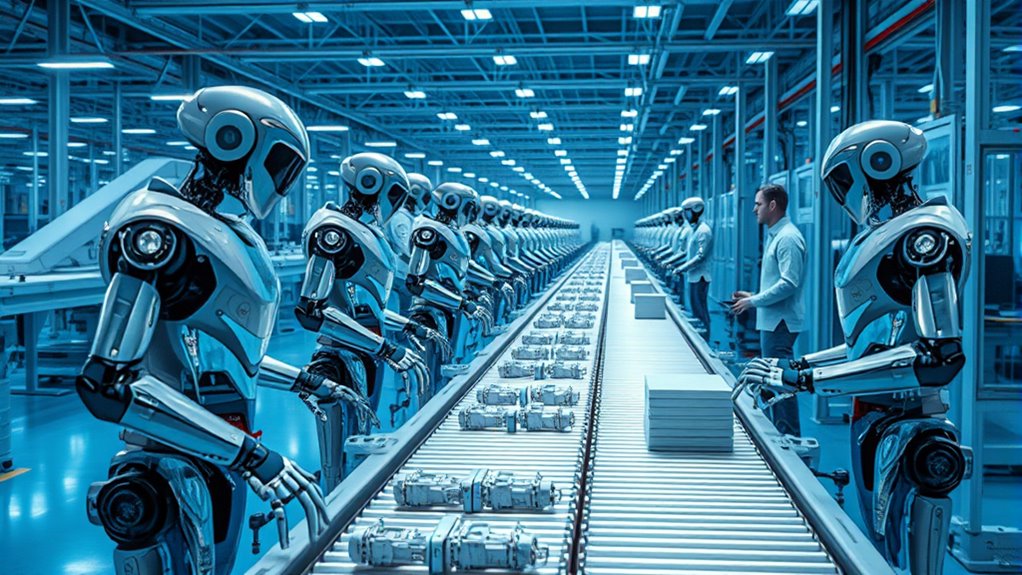

By 2030, automation and robotics will reshape your industry by boosting efficiency, reducing costs, and enabling smarter decision-making through AI, IoT, and advanced control systems. You’ll see more tasks automated, from manufacturing to healthcare, with increased safety and customization. While jobs may shift and require new skills, widespread adoption promises economic growth and innovation. Stay informed about these changes, as you’ll discover how to adapt and thrive in this evolving landscape.

Key Takeaways

- By 2030, automation could handle up to 42% of manufacturing tasks, significantly boosting efficiency and reducing labor costs.

- Emerging AI, IoT, and digital twin technologies will enable smarter, self-optimizing factories with real-time decision-making capabilities.

- Automation may create 170 million new jobs while displacing around 92 million, emphasizing the need for workforce reskilling.

- Industry standards and cybersecurity advancements will be essential to ensure safe, secure, and interoperable autonomous systems.

- The global economy could gain up to $15.7 trillion from automation-driven productivity and innovation by 2030.

The Accelerating Growth of the Automation Market by 2030

The automation market is set to experience rapid growth by 2030, driven by increasing demand for operational efficiency, cost reduction, and sustainable manufacturing practices. By then, the global factory automation market is forecasted to reach USD 281.9 billion, growing at a CAGR of 9.1%. Industrial automation is expected to hit USD 149.3 billion, expanding at 7.2%, while manufacturing automation could grow at nearly 10%. Overall, the automation sector might reach around USD 238 billion by 2030 with a 7.2% CAGR. This growth is fueled by the need to boost productivity, address labor shortages, and adopt eco-friendly practices. As industries invest more in advanced robotics, AI, and IoT, your sector will increasingly rely on automation to stay competitive and efficient. Additionally, innovations in bedroom design and interior aesthetics reveal how automation could also influence personal spaces in the future. Moreover, the integration of exfoliation techniques like glycolic acid into skincare routines exemplifies how advanced technologies are transforming daily practices and industry standards. Furthermore, the adoption of industrial robotics is expected to significantly enhance manufacturing processes, reducing errors and increasing throughput. The deployment of automation will also likely lead to improved quality control and product consistency across various industries. As these technologies continue to evolve, they will also promote sustainable practices, helping industries reduce their environmental impact while maintaining high standards of productivity.

Key Technologies Driving Industry Transformation

You’ll see AI and machine learning revolutionize how industries analyze data, predict maintenance, and optimize operations. IoT will connect devices to provide real-time insights, making processes more proactive and efficient. Advanced control systems will guarantee seamless integration of these technologies, transforming manufacturing and supply chains alike. These integrated systems will enable smarter decision-making and greater AI-driven adaptability, ensuring industries stay competitive in the rapidly evolving landscape. Incorporating GMC tuning techniques can help create flexible and adaptable work environments that support these technological advancements. Additionally, understanding the divorce process and requirements in various regions can help industries better navigate international legal challenges related to workforce mobility and organizational restructuring.

AI and Machine Learning Integration

AI and machine learning are rapidly transforming industries by enabling smarter automation, real-time data analysis, and adaptive processes. You’ll see industries leverage these technologies to improve decision-making, optimize operations, and reduce costs. For example, AI-driven predictive analytics support maintenance scheduling, minimizing machinery failures and outages. In manufacturing, over half of companies are piloting AI to refine operations and workforce impacts, with many elevating AI initiatives to strategic levels. Integration with robotics enhances assembly lines, logistics, and inspection tasks, cutting errors and expenses. As adoption accelerates—expected to grow at a CAGR of 10.8%—more jobs will shift toward managing AI systems, data analysis, and cybersecurity. Additionally, ongoing innovations in edge computing are enabling faster data processing directly at the source, further enhancing the efficiency of automated systems. This integration is laying the foundation for a future where automation and AI work seamlessly to boost productivity and reshape industries. The implementation of vertical storage solutions and other organization strategies can further optimize these automated environments for maximum efficiency, especially as adaptive algorithms become more sophisticated and capable of handling complex tasks with minimal human intervention. Furthermore, advancements in cybersecurity are essential to protect these increasingly interconnected automated systems from emerging threats, ensuring reliable operations. As these technologies evolve, the importance of data security will only grow to safeguard sensitive information across sectors. Incorporating advanced sensors into these systems also enhances real-time monitoring and responsiveness, further driving efficiency and safety.

IoT for Data Collection

As industries increasingly adopt AI and machine learning, the backbone of this transformation lies in the vast network of IoT devices collecting critical data. You’ll see over 18 billion IoT devices by 2025, with projections surpassing 22.4 billion by 2026, fueling rapid industry change. These devices enable real-time monitoring, allowing you to track temperature, pressure, vibration, and more through sensors. Cameras and smart vision systems automate quality inspections, while industrial gateways transmit data efficiently. Wireless and wired networks support uninterrupted data flow, and edge computing processes data locally, reducing latency. IoT adoption is accelerating across regions, with Asia-Pacific leading the growth due to manufacturing expansion. Here are three ways IoT data collection transforms your industry: 1. Reduces manual monitoring and human error 2. Enables faster responses to process issues 3. Supports predictive maintenance and continuous optimization. Leveraging industrial sensor networks enhances data accuracy and system reliability, further streamlining operations.

Advanced Control Systems

Advanced control systems are at the core of industry transformation, driven by emerging technologies that enable machines to operate more autonomously and efficiently. You’ll see AI and machine learning powering self-optimizing and self-diagnosing systems, reducing the need for human intervention. Digital technologies like data analytics and digital twin simulations help optimize performance and predict potential issues, boosting productivity. The integration of 5G and edge computing ensures real-time data processing and communication, making automation faster and more reliable. As autonomous control systems become more prevalent, industries will benefit from smarter factories that adapt quickly to changing conditions. These innovations are expected to significantly accelerate the adoption of automation technologies across various sectors. By 2030, these advanced control systems will be deeply embedded in enterprise ecosystems, revolutionizing how industries operate and innovate. Additionally, the increasing emphasis on transparency and responsible investing in private equity will drive the development of more sophisticated and accountable automation solutions. Incorporating industry-specific standards will further enhance the safety and interoperability of these systems. Moreover, the integration of emerging safety protocols ensures these automated systems operate within secure and reliable parameters. Furthermore, advancements in AI security will be crucial for protecting these autonomous systems from cyber threats, ensuring their integrity and resilience. For example, cybersecurity measures tailored for industrial environments will become essential to defend against evolving cyberattacks.

Government Initiatives Fueling Automation Adoption

Governments worldwide are actively shaping the future of manufacturing by implementing initiatives that promote automation adoption. These efforts aim to boost competitiveness, innovation, and sustainability. Here are three key ways they’re doing this:

Global governments are driving manufacturing innovation through policies, funding, and regulations supporting automation.

- National initiatives like China’s “Made in China 2025” and India’s “Make in India” focus on upgrading manufacturing with automation, supported by policies encouraging domestic growth.

- Funding and incentives such as grants, tax credits, and public-private partnerships help businesses, especially SMEs, develop and implement automation solutions.

- Regulatory frameworks set targets for automation, promote safer autonomous systems, and include workforce upskilling, reducing barriers and aligning with Industry 4.0 goals. The global automation market is projected to reach $307.7 billion by 2030. These initiatives create a fertile environment for automation to flourish across industries worldwide.

Economic Benefits and Workforce Implications

Automation and AI are poised to remarkably boost the global economy by 2030, potentially adding up to $15.7 trillion through increased productivity and consumer spending. You’ll see productivity rise, especially in the US, with annual gains of 0.5 to 0.9 percentage points. China and North America could experience GDP boosts of 26% and 14.5%. Automation allows less specialized workers to perform expert tasks, improving efficiency across sectors.

| Sector | Automation Impact | Economic Potential |

|---|---|---|

| Manufacturing | Automates 42% of task time | Significant economic output |

| Healthcare | Streamlines patient care | Improved service delivery |

| Construction | Adoption lagging behind | Uneven growth |

While 170 million new jobs may emerge, 92 million could be displaced, emphasizing the need for reskilling and adaptation.

Emerging Skills and Job Opportunities in Automated Industries

As automation advances, you’ll need to develop new technical skills like AI, machine learning, and data analytics to stay competitive. Growing maintenance roles will require specialized expertise to keep automated systems running smoothly. Upskilling now guarantees you’re prepared for these emerging opportunities and can adapt to ongoing industry changes. Automation will also create new roles in system design, cybersecurity, and ethical AI management, further expanding the landscape of future job prospects.

New Technical Skill Sets

By 2030, thriving in automated industries will require developing new technical skills that keep pace with rapid technological advancements. To stay competitive, you’ll need to focus on emerging skills such as:

- AI and Machine Learning Expertise – mastering these will open doors to designing and improving intelligent systems.

- Data Literacy and Analytics – understanding how to analyze large datasets will be crucial for making informed decisions.

- Cybersecurity Skills – protecting automated systems from threats will be increasingly essential as reliance on digital infrastructure grows.

These skills will lead to new job opportunities like AI engineers, data analysts, and cybersecurity specialists. Staying ahead means continuously updating your technical knowledge and adapting to evolving industry demands.

Growing Maintenance Roles

The increasing integration of automated systems has expanded maintenance roles, creating a high demand for technicians skilled in diagnosing, repairing, and managing robotic equipment. You’ll find opportunities in predictive and preventive maintenance driven by AI, requiring skills in troubleshooting complex robotic systems. Supervisory roles overseeing automated production lines are also growing, along with process optimization positions to boost efficiency. As robotic equipment becomes more prevalent, the need for installers and repairers surges. You’ll need to develop expertise in managing, calibrating, and maintaining robotic systems, including IoT device integration and AI diagnostic tools. Safety protocols for working alongside robots are essential. With traditional manual jobs declining, these emerging maintenance roles offer stable, long-term careers for those willing to adapt and acquire new technical skills.

Upskilling for Future

Advancements in automation are reshaping the skills needed for future jobs, making upskilling more important than ever. To stay competitive, you need to focus on emerging skills that align with the evolving industry landscape. Here are three key areas to prioritize:

- Artificial Intelligence (AI) – As automation expands, AI expertise will be in high demand for developing and managing intelligent systems.

- Big Data and Analytics – Making sense of vast data sets is essential for informed decision-making in automated environments.

- Cybersecurity – Protecting digital systems is critical as reliance on automation grows, creating opportunities for cybersecurity specialists.

Challenges and Considerations for a Fully Automated Future

Achieving a fully automated future presents numerous challenges that organizations must address to succeed. Market growth is promising, but significant investments in technology and infrastructure are necessary. Supply chain disruptions, like semiconductor shortages, and fluctuations in raw material and energy prices can delay adoption. Technologically, integrating soft PLCs, teach-less robotics, 5G, and digital twins requires overcoming compatibility issues and managing technical debt from legacy systems. Data synchronization is critical; disconnects between manufacturing and engineering systems hinder efficiency. Industry-specific hurdles, such as cybersecurity risks and varied technology adoption levels, complicate progress. Companies must adapt quickly to evolving demands and advancements, balancing costs with operational gains. Continuous maintenance and strategic investments are essential to navigate the complexities of a fully automated industry.

Frequently Asked Questions

How Will Automation Impact Global Employment Levels by 2030?

You’ll see automation displacing up to 800 million jobs globally by 2030, especially in routine tasks and administrative roles. But, it also creates around 170 million new jobs, mainly in tech and high-skill sectors. To stay ahead, you’ll need to embrace continuous learning and reskilling. While some workers face displacement, the overall impact on employment depends on how quickly you adapt and develop new skills.

What Measures Are in Place to Ensure Cybersecurity in Automated Industries?

You’re facing an unprecedented cybersecurity challenge—your industry’s safety relies on it. To protect your systems, you use encryption to guard sensitive data, network segmentation to isolate critical assets, and intrusion detection to catch threats early. Endpoint security shields your devices, while continuous monitoring ensures real-time threat response. Advanced measures like SCADA security, AI-driven detection, and incident planning create a fortress, keeping your industry safe amidst the relentless cyber threat landscape.

How Accessible Are Automation Technologies for Small and Medium-Sized Enterprises?

Automation technologies are becoming increasingly accessible to small and medium-sized enterprises. You can start small with simple tasks like social media posting or customer inquiries, gradually expanding as you build capability. Cloud-based AI-as-a-Service options reduce infrastructure costs, making adoption easier. Upskilling your staff and negotiating with vendors also help lower barriers. While upfront costs and integration challenges exist, many SMEs see automation as a way to boost efficiency without massive investments.

What Ethical Concerns Arise With Increased Reliance on Ai-Driven Automation?

They say, “With great power comes great responsibility,” and AI-driven automation is no exception. As you rely more on AI, ethical concerns like bias and discrimination, job loss, data privacy, and cybersecurity risks grow. You might also face transparency issues and widening inequality. It’s crucial to address these concerns proactively to guarantee AI benefits everyone, not just a few, and maintains public trust.

How Will Automation Influence Consumer Prices and Product Quality?

Automation will likely lower your costs and lead to more affordable products, thanks to reduced operational expenses and increased efficiency. It also enhances product quality through better consistency, personalization, and innovation, making your purchases more reliable and tailored to your needs. As automation boosts productivity and market growth, you might see a wider variety of high-quality, cost-effective options, shaping a more consumer-focused, competitive marketplace by 2030.

Conclusion

While automation may seem intimidating, it’s also opening doors to new opportunities. Yes, some jobs will change or disappear, but many will evolve into roles that require human creativity and oversight. Embracing these shifts now can position you ahead of the curve. Don’t fear the future—see it as a chance to develop new skills and thrive in an increasingly automated world. Adaptability is your best tool in this exciting transformation.