Human-robot teams are transforming work by boosting productivity, safety, and accuracy. Cobots handle repetitive or hazardous tasks, freeing you to focus on complex and creative activities. Technological innovations, like AI and sensor fusion, make these collaborations safer and more adaptable. While adopting robots presents challenges such as costs and integration, the future promises seamless teamwork and new skills. Keep exploring how these changes are shaping your workplace and opportunities ahead.

Key Takeaways

- Human-robot collaboration boosts productivity by automating repetitive and hazardous tasks while allowing humans to focus on strategic activities.

- Safety is enhanced through sensors, force limits, and virtual zones, enabling robots and humans to work side-by-side securely.

- Workforce roles shift from manual labor to supervisory, maintenance, and programming, requiring new skills and continuous learning.

- Advanced AI and sensor technologies enable real-time environmental awareness, improving decision-making and responsiveness in collaborative settings.

- Ethical and integration challenges, such as costs and market fragmentation, must be addressed to maximize the benefits of human-robot teamwork.

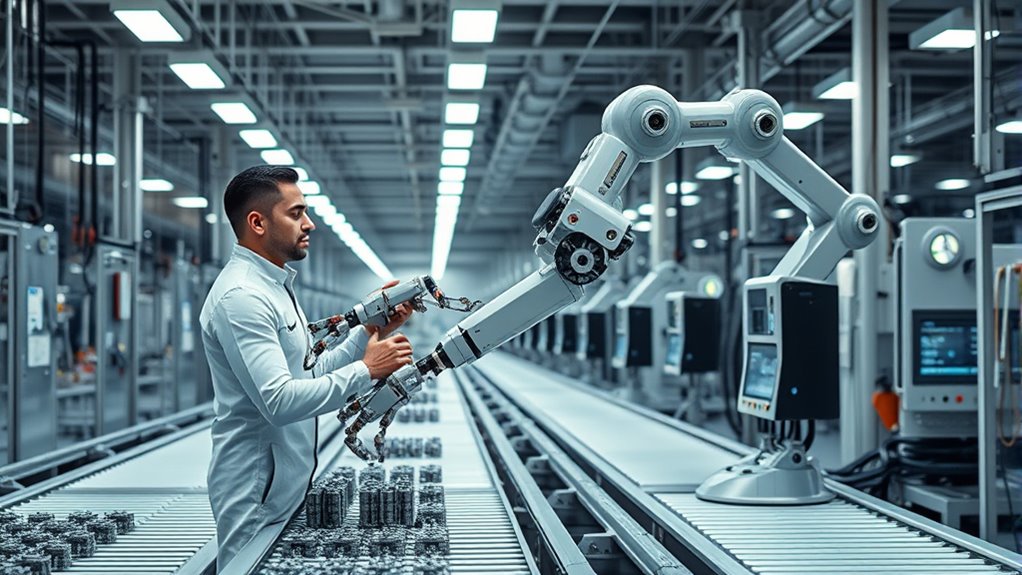

The Rise of Collaborative Robots in Today’s Workplaces

The rise of collaborative robots, or cobots, is transforming modern workplaces by enabling humans and machines to work side by side more safely and efficiently. The market for cobots is expected to grow from $3.28 billion in 2024 to over $12 billion by 2029, with a compound annual growth rate of nearly 31%. Their adoption is driven by rising labor costs, expanding industrial sectors, and the demand for automation. Cobots made up 10.5% of all installed industrial robots in 2023 and are projected to represent 34% by 2025. Advancements like AI integration and innovative product launches are fueling this growth. Companies are investing heavily in research and forming strategic partnerships to develop safer, more capable cobots that seamlessly fit into diverse work environments. Relationships – Personality Test insights can also guide companies in fostering better team dynamics and collaboration in human-robot interactions. Additionally, the development of cobots often involves considerations similar to the Ice Cream Quality and Ingredients, ensuring that these machines operate with high standards of safety and reliability to meet industry demands. Incorporating projector technology insights can further optimize the deployment of visual systems in collaborative settings, enhancing communication and training. Exploring home decor concepts like wall organization and aesthetic design principles can also inspire innovations in workspace ergonomics and environment customization for human-robot teams. Furthermore, integrating creative unique and wicked planters into workspaces could improve the aesthetics and boost employee well-being in collaborative environments.

How Human and Robotic Teams Enhance Productivity

When you combine human skills with robotic automation, productivity levels skyrocket. Robots handle repetitive tasks with precision, reducing human error and freeing you to focus on strategic work. Together, your team becomes more efficient, accurate, and ready to meet demanding goals. AI-driven automation further enhances this synergy by continuously learning and optimizing workflows for even greater performance. Incorporating essential oils for productivity can also help improve focus and reduce stress in a collaborative work environment.

Boosting Efficiency Levels

Integrating human and robotic teams markedly boosts efficiency by leveraging the strengths of both. Automated systems handle high-volume, repetitive tasks faster and more accurately, reducing errors and rework. Intelligent scheduling optimizes workforce deployment in real time, minimizing idle time. Automation in customer service enables instant responses and 24/7 availability, speeding up service delivery. Data entry and invoice processing happen at machine speed, freeing staff for complex activities. This integration enhances productivity, with AI-driven tools potentially adding $4.4 trillion globally. Robots operate nonstop, supporting continuous operations and flexible scaling. They optimize resource use, from supply chains to maintenance, preventing downtime. Human-robot collaboration shifts focus from routine tasks to strategic work, maximizing efficiency and driving long-term business growth. Proper storage conditions for equipment and tools also play a vital role in maintaining high operational standards and preventing disruptions. Additionally, workplace safety is improved as robots can handle hazardous environments, reducing workplace accidents and promoting a safer work environment. Implementing tuning strategies similar to those used in vehicle modifications can further enhance operational performance and adaptability. Moreover, understanding the security implications of robotic integration ensures that sensitive data and systems remain protected against cyber threats. Drawing from Honda Tuning techniques, organizations can fine-tune their processes to achieve optimal performance and responsiveness.

Reducing Human Error

Combining human judgment with robotic precision considerably reduces errors in collaborative tasks. Error detection and correction algorithms play a key role, correcting posture inaccuracies and leveraging multimodal responses to identify issues quickly. Proactive systems spot problems faster than reactive ones, preventing errors from escalating. Implicit detection methods, like facial expressions and speech patterns, can identify up to 38.5% of errors without human input. Robots trained with prior knowledge make fewer mapping mistakes, and continuous learning helps improve gesture-action accuracy over time. In collaborative environments, robots provide real-time feedback, preventing mistakes before they happen. Social signals can serve as universal cues for error detection and classification, enhancing the robustness of error management systems. Incorporating error mitigation strategies based on these signals further reduces the likelihood of mistakes. Additionally, integrating AI-driven analytics can help identify patterns of errors over time, enabling more targeted improvements in team workflows. The use of machine learning techniques can adapt error detection systems to specific team dynamics, increasing effectiveness. As AI technologies advance, trustworthiness in collaborative AI systems becomes increasingly important to ensure reliable performance. Developing adaptive systems that can evolve with team needs ensures sustained accuracy and efficiency. This proactive approach fosters trust, reduces misunderstandings, and enhances team performance—leading to fewer errors, higher productivity, and smoother human-robot cooperation.

Technological Innovations Powering Human-Robot Collaboration

Technological innovations like AI integration, soft robotics, and advanced sensors are transforming how humans and robots work together. These tools make collaboration safer, more adaptable, and more efficient, allowing robots to respond intelligently and gently to human needs. As these technologies evolve, they create new possibilities for seamless, productive teamwork across industries. AI-driven real-time adaptation enhances robots’ ability to dynamically respond to changing environments, further improving safety and efficiency in collaborative settings.

AI Integration Advancements

Advancements in AI integration are transforming how humans and robots work together, enabling machines to operate with greater autonomy and adaptability. Self-learning algorithms allow robots to adjust to new tasks without needing reprogramming, while real-time environmental sensing enhances their situational awareness for safer interactions. AI-driven decision-making supports complex problem solving in unstructured environments, broadening robotic applications. Emotional intelligence modules foster natural communication, making interactions more effective. Autonomous systems now include self-diagnostics and enhanced sensor fusion, improving maintenance and environmental understanding. Edge AI reduces response latency, enabling smoother collaboration. Natural language processing and gesture recognition simplify communication, and programming by demonstration allows non-experts to teach robots easily. Additionally, ongoing developments in AI-powered computer vision enable robots to better identify objects and understand their surroundings, further enhancing their ability to collaborate effectively with humans. The continuous improvement of robotic autonomy also contributes to creating a more responsive, safe, and efficient human-robot partnership. Furthermore, integrating home heating solutions with AI technologies can optimize environmental comfort and energy efficiency in shared workspaces. For example, integrating smart environmental controls helps adapt workspaces dynamically to human needs and robot operations, promoting a more harmonious environment. As AI systems become more context-aware, they can better anticipate human needs and respond adaptively, fostering more seamless collaboration. Additionally, leveraging AI security principles ensures that these advanced systems remain protected from cyber threats, maintaining operational integrity and safety.

Soft Robotics Flexibility

Soft robotics has revolutionized human-robot collaboration by emphasizing safety, adaptability, and intuitive interaction. You benefit from compliant and flexible materials that allow gentle, natural movements, reducing injury risk. These robots can conform to changing environments, enabling safe handling of delicate objects and seamless interaction with humans of all ages. Advances in precise motion control—through antagonistic designs and self-sensing systems—boost their reliability for tasks like electronics assembly. Biomimetic designs and pneumatic systems enhance flexibility and safety, while cable and motor systems provide accurate actuation. The ultra-low hysteresis in soft robots ensures consistency, and drag teaching allows intuitive programming. Overall, their adaptability and safety features make soft robots ideal partners in diverse industries, fostering more collaborative and responsive human-robot teams. Research in soft robotics also supports the development of haptic feedback systems, further enhancing human-robot interaction and collaboration.

Sensor Safety Technologies

Sensor safety technologies are transforming how humans and robots work together by providing real-time environmental awareness and precise control. You’ll find a range of sensors like laser scanners, light curtains, radar, 3D cameras, and proximity sensors working at high frame rates—90 Hz or more—to deliver rapid, accurate feedback. These sensors enable robots to dynamically adjust force, speed, and movement based on human proximity, enhancing safety. Multiple sensing modes support speed and separation monitoring, safety-rated stops, and tooling feedback. Sensor fusion combines data from different sensors for all-encompassing situational awareness, reducing risks. This tech allows humans and robots to share workspaces safely, adapt older robots for collaboration, and execute complex tasks—making automation more flexible, efficient, and safe.

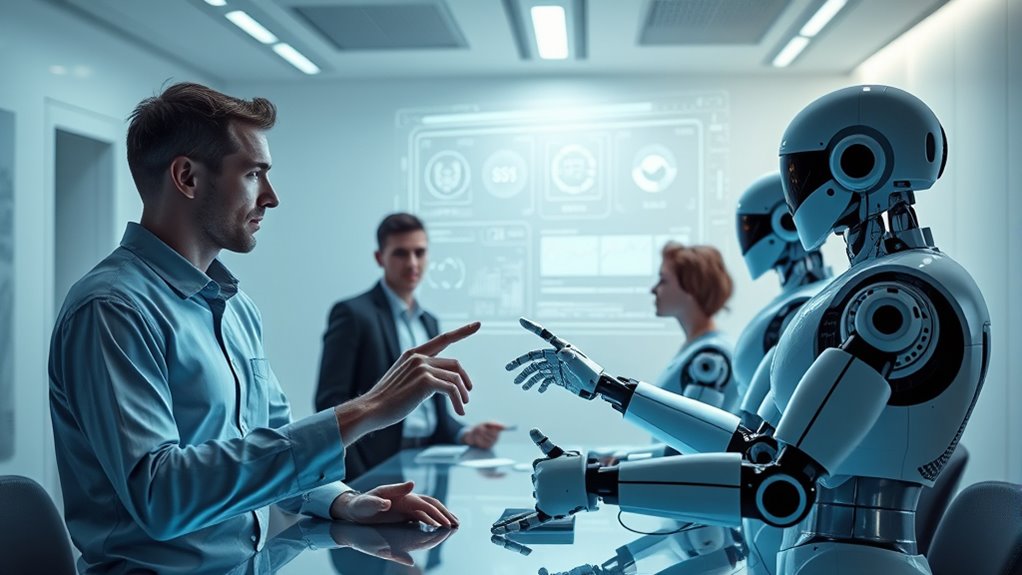

Transforming Roles and Responsibilities in the Workforce

As robotics and AI technologies become more integrated into workplaces, they are fundamentally changing the roles and responsibilities of employees. You’ll find that tasks once done manually, like repetitive or hazardous work, are now automated. This shift creates new roles, such as supervising, maintaining, or programming automation systems. Imagine:

- A technician monitoring robotic systems to ensure smooth operation.

- An operator troubleshooting AI-driven machinery during production.

- A supervisor designing workflows that leverage human-robot collaboration.

While some jobs are displaced—about 14% of workers—others evolve, emphasizing skills like creativity, problem-solving, and emotional intelligence. As a result, your role shifts from manual labor to strategic oversight, continuous learning, and working alongside intelligent machines.

Safety and Efficiency: Benefits of Cobot Integration

Integrating cobots into your workflow considerably improves safety by reducing injuries and preventing accidents in hazardous tasks. They also boost efficiency by handling repetitive work quickly, allowing your team to focus on more complex activities. With features that minimize human error, cobots create a safer, more productive environment for everyone.

Enhanced Workplace Safety Measures

Enhanced workplace safety is a key advantage of cobot integration, as these collaborative robots are designed to work safely alongside humans. Imagine a workspace where:

- Hazardous tasks are handed off to cobots, reducing your risk of injury.

- Built-in sensors and force-limiting mechanisms prevent accidents before they happen.

- Virtual zones and speed limits keep robots and humans working safely side by side.

Cobots operate at lower speeds and include advanced safety features like vision systems and safety analytics, making the environment safer. Regular training and safety protocols are essential to keep everyone aware and protected. By integrating cobots thoughtfully, you create a safer, more secure workplace where humans and robots collaborate seamlessly.

Increased Operational Efficiency

Cobots markedly boost operational efficiency by enabling continuous, around-the-clock productivity without fatigue. They handle repetitive tasks consistently, reducing downtime and increasing output. After integrating cobots, companies like AIM Processing saw productivity soar by 400%, and McKinsey estimates up to a 20% boost industry-wide. Task Force Tips streamlined operations and cut labor costs with vision-guided cobots, demonstrating their cost-effectiveness. Cobots are easy to reprogram and integrate into existing lines, allowing quick adjustments for new products or processes. This flexibility helps manufacturers respond rapidly to market shifts. By taking on physical, repetitive work, cobots free human workers to focus on complex, value-added tasks, optimizing labor use and improving overall workflow. The result is a more efficient, adaptable, and competitive operation.

Reduced Human Error Risks

By automating hazardous and repetitive tasks, cobots substantially reduce workplace injuries and human errors. You’ll see fewer accidents because cobots handle dangerous environments, lowering injury rates by up to 72%. They also reduce ergonomic strain, helping prevent musculoskeletal issues. With precise and consistent task execution, cobots minimize physical mishaps caused by human fatigue or inattention. Imagine this:

- Cobots working alongside humans, avoiding collisions with sensors and safety features.

- Robots following strict protocols, reducing deviations from standard procedures.

- Automated monitoring systems catching errors before they escalate.

These features make your workspace safer by preventing mistakes and injuries, while boosting operational reliability. Trust in cobots’ accuracy and safety design helps create a safer, more efficient environment where human errors are significantly minimized.

Industry-Specific Applications of Human-Robot Partnerships

Industry-specific applications of human-robot partnerships demonstrate how tailored collaboration improves efficiency, safety, and quality across sectors. In manufacturing, cobots handle repetitive or heavy tasks, freeing you to focus on complex work, boosting productivity and process flexibility. Logistics teams rely on robots to sort, pack, and transport goods, reducing manual effort while maintaining safety through sensors and AI. Automotive assembly lines use robots for welding and heavy lifting, with humans overseeing assembly and inspection, resulting in faster cycle times. In healthcare, robots assist in surgeries, patient care, and disinfection, enhancing precision and reducing physical strain. Food processing benefits from robots that handle high-speed sorting and packaging, ensuring hygiene and safety standards. Across industries, human-robot collaboration adapts to specific needs, optimizing operations while maintaining safety and quality.

Overcoming Challenges in Adopting Robotic Technologies

Adopting robotic technologies presents a range of challenges that organizations must address to realize their full potential. First, the high initial costs and uncertain ROI make many hesitant. Second, complex integration processes, environmental constraints like space, floor conditions, and climate factors, complicate deployment. Third, technological limitations such as system inflexibility and lack of standardization hinder performance. Imagine trying to fit a new robot into a cramped workspace, battling uneven floors, or dealing with inconsistent power supplies. These obstacles can feel overwhelming, especially when choosing vendors, managing fragmented markets, or lacking skilled support. Overcoming these hurdles requires strategic planning, investment, and collaboration to turn robotic solutions into seamless, effective tools in your operations.

The Future Landscape of Human-Robot Coexistence

How will advancements in robotics and artificial intelligence reshape the way humans and robots work together? You’ll see cobots evolving from simple assistive tasks to sharing workspaces, collaborating seamlessly on the same projects. AI enhancements, like real-time stress and emotion monitoring, allow robots to adapt their actions for better safety and ergonomics. Foundational robot platforms with integrated AI expand applications beyond manufacturing and logistics, enabling diverse roles across industries. AI agents such as Manus and advanced LLMs accelerate integration into various job functions. Improved safety systems foster more secure interactions, reducing accidents and building trust. These innovations will lead to a future where human-robot teamwork is highly integrated, dynamic, and efficient, transforming workplaces into environments where humans and robots complement each other’s strengths in everyday tasks.

Skills and Training for the New Age of Robotics

As robotics and AI become more integrated into the workplace, your skills need to evolve to keep pace with these technological advances. You’ll need to develop technical proficiency in operating, programming, and troubleshooting robotic systems. Continuous learning is essential, so stay updated on new tools and methods. Additionally, adaptability is key as automation shifts job roles, requiring you to change focus and approaches. To succeed, focus on these areas:

- Master robot mechanics, software, and safety protocols through technical training.

- Cultivate soft skills like communication and teamwork for effective human-robot collaboration.

- Strengthen problem-solving abilities to navigate complex robotic integration challenges.

Ethical and Regulatory Considerations in Human-Robot Work Environments

Ethical and regulatory considerations are critical when integrating robots into human work environments, as they directly impact safety, privacy, and trust. You need to address job displacement by implementing retraining programs, ensuring workers aren’t left behind. Protecting data privacy is essential, especially when sensitive information is collected during interactions. Workers must be informed about how robots are used and their benefits through clear communication. Involving users in the design process helps ensure robots meet their needs and expectations, fostering acceptance. Regulatory frameworks should include safety protocols, risk assessments, and compliance standards to prevent accidents and hazards. International cooperation can help standardize rules, making human-robot collaboration safer and more effective across industries. Ultimately, ethical and regulatory considerations cultivate trust and promote responsible integration.

Frequently Asked Questions

How Do Cobots Adapt to Rapidly Changing Industry Needs?

You see, cobots adapt to industry changes quickly by being highly flexible and easy to reprogram. You can swiftly switch their tasks based on market demands, allowing your operations to pivot without delays. Their seamless integration into workflows means you don’t have to overhaul your entire system. Plus, their safety features let you reconfigure tasks on the fly, keeping your production line efficient and responsive to evolving needs.

What Are the Key Factors Influencing Robot Integration Costs?

You should consider that robot integration costs depend on initial hardware prices, which vary based on complexity and application needs. Installation, customization, and software licensing also play significant roles. Additionally, training personnel, ongoing support, and maintenance add to expenses. The level of system compatibility, retrofitting requirements, and safety compliance influence costs further. All these factors combined determine the total investment needed to successfully integrate robots into your operations.

How Do Companies Address Employee Concerns About Robotics Replacing Jobs?

You might think robots will steal your job, but companies often work hard to ease those fears. They communicate openly, offer training programs, and redefine roles to help you work alongside automation. By involving you in planning, providing upskilling opportunities, and promoting a culture of learning, they aim to turn automation into a career growth tool rather than a threat. This approach helps you adapt and thrive in evolving workplaces.

What Measures Ensure Data Security in Human-Robot Collaborative Environments?

You can guarantee data security in human-robot collaborative environments by implementing extensive cybersecurity measures. Use encryption to protect data transmission, enforce strict access controls, and segment networks to minimize risks. Regularly update systems with security patches, deploy firewalls and intrusion detection tools, and develop clear data security policies. Train personnel on cybersecurity best practices, establish secure communication protocols, and adhere to industry standards to maintain a resilient and secure workspace.

How Will AI Advancements Impact the Future Roles of Human Workers?

You might think AI will take over every job, but it’s more like a superhero sidekick than a villain. You’ll see your roles evolve dramatically, especially in creative and complex tasks. Instead of replacement, AI will uncover new opportunities, making your skills more valuable. You’ll need to adapt and learn new things, but in this future, you’ll work alongside AI to achieve extraordinary things, transforming your work life forever.

Conclusion

As you embrace human-robot collaboration, remember that over 60% of companies report increased productivity with cobots. By adapting your skills and staying open to innovation, you’ll thrive in this evolving workplace. The future promises even smarter, safer teamwork—so get ready to work alongside bots and open new possibilities. Embracing these changes isn’t just beneficial; it’s essential for staying competitive in tomorrow’s world of work.